Unlock Durability: The Secret to a Long-Lasting Faucet Handle

OEM Zamak Faucet Handles offer exceptional durability and performance. They represent the secret to a long-lasting product. These handles are meticulously engineered for superior longevity. They also provide an enhanced user experience. Manufacturers design each Faucet Handle with unique material properties and advanced manufacturing techniques. These elements significantly contribute to their robust nature and sustained function.

Key Takeaways

- Zamak faucet handles last a long time. They are made from strong metals like zinc, aluminum, magnesium, and copper.

- These handles are very strong but not too heavy. Manufacturers can easily make them into many cool shapes and designs.

- Zamak handles do not get scratched or broken easily. They also resist rust and damage from water or cleaning stuff.

- OEM Zamak handles come in many styles like shiny chrome or cool matte black. These finishes protect the handle and make it look good.

- These handles are good for your health. They can have special coatings that stop germs from growing on them.

- Zamak is good for the planet. You can recycle it completely, and making it creates less pollution.

- Choosing Zamak handles means you get a reliable product. It saves money because you will not need to replace it often.

Understanding Zamak: The Foundation of a Durable Faucet Handle

What is Zamak?

Zamak represents a family of Zinc Alloys. Manufacturers specifically engineer these alloys for casting applications. The name "Zamak" is an acronym derived from the German names for its constituent metals: Zink (zinc), Aluminium (aluminum), Magnesium (magnesium), and Kupfer (copper). This unique combination of elements gives Zamak its distinct properties.

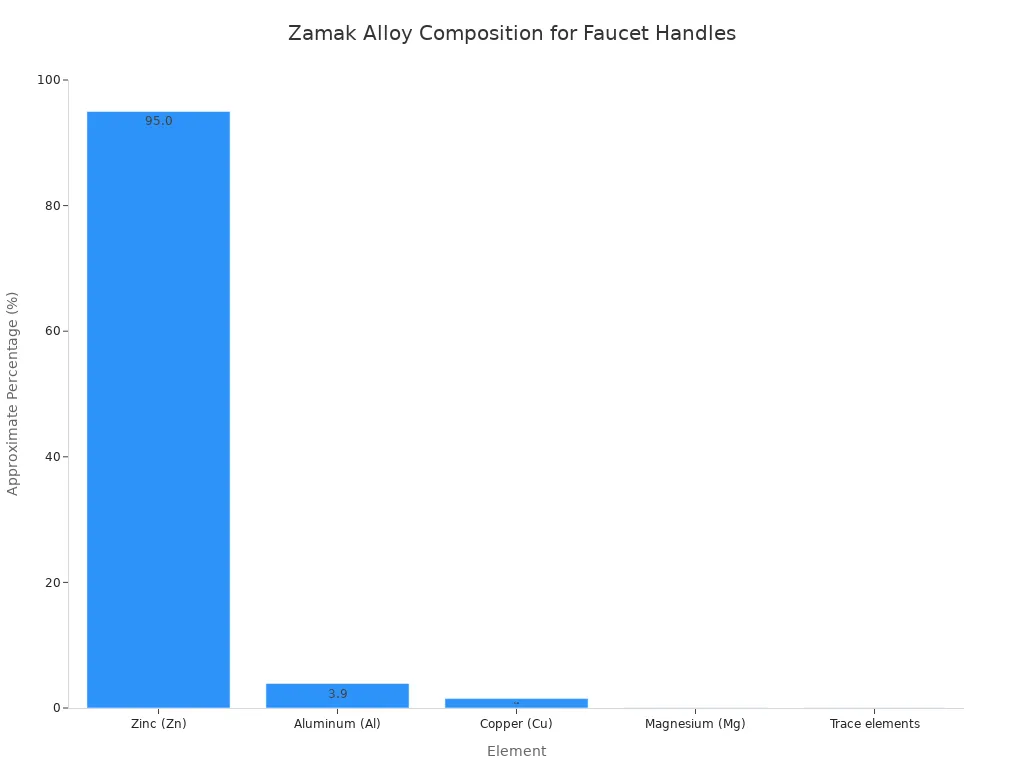

Zinc Alloy Composition

Zamak alloys primarily consist of zinc. They also include specific percentages of other metals. These additional elements enhance the alloy's mechanical properties. The table below details the approximate percentage range of elements found in common Zamak alloys:

| Element | Approximate Percentage Range |

|---|---|

| Zinc (Zn) | 94–96% |

| Aluminum (Al) | 3.5–4.3% |

| Copper (Cu) | 0–3% |

| Magnesium (Mg) | ~0.03% |

| Trace elements (Iron, Nickel, Tin) | <0.1% |

Key Elements and Their Roles

Each element in Zamak plays a crucial role. Zinc forms the base metal. Aluminum improves strength and hardness. Copper further increases strength and reduces grain size. Magnesium helps prevent intergranular corrosion. Different Zamak formulations exist for various applications:

- Zamak 3: This alloy primarily contains 96% Zinc and 4% Aluminum. It serves as a standard alloy due to its excellent balance of properties.

- Zamak 5: This variant features added Copper (around 1%). The copper content provides increased strength and hardness.

- Zamak 7: This alloy offers improved fluidity during casting. It also has a lower magnesium content.

- Zamak 2: This formulation contains approximately 3% Copper. It offers the highest strength among Zamak alloys but exhibits reduced ductility. Zamak alloys find common use in hardware applications. These include handles and plumbing accessories like mixer taps. The term 'mixer zamak brass' indicates Zamak as a material component in water mixer tap construction.

Why Zamak Excels for Faucet Handles

Zamak offers several advantages, making it an ideal material for faucet handles.

Superior Strength-to-Weight Ratio

Zamak provides impressive strength without excessive weight. This characteristic ensures a robust and durable product. It also maintains a comfortable feel for the user.

Excellent Castability and Formability

Manufacturers can easily cast Zamak into intricate shapes. This excellent castability allows for complex designs and precise detailing. It ensures the production of aesthetically pleasing and ergonomically sound Faucet Handles.

Cost-Effectiveness in Production

Zamak offers a cost-effective solution for manufacturing. Its efficient casting process reduces production costs. This allows brands to deliver high-quality, durable products at a competitive price point.

Core Features of OEM Zamak Faucet Handles

OEM Zamak Faucet Handles offer a combination of features that set them apart. These characteristics ensure superior performance and user satisfaction. Manufacturers design these handles for reliability and aesthetic appeal.

Unmatched Durability and Longevity

Zamak's inherent properties contribute significantly to the long life of these handles. They withstand the rigors of daily use.

Resistance to Wear and Tear

Zamak alloys possess high surface hardness. This property makes them highly resistant to abrasion and scratching. Daily turning and handling do not easily degrade the handle's surface. This ensures the handle maintains its original appearance and function over many years.

Impact Resistance for Daily Use

Accidental bumps or drops can damage lesser materials. Zamak, however, exhibits excellent impact strength. This resilience protects the handle from damage during everyday use. It prevents cracks or breaks that might occur with sudden impacts.

Sustained Performance Over Time

OEM Zamak handles maintain their structural integrity and smooth operation for extended periods. Their robust composition resists material fatigue. This means the handle will continue to function precisely, cycle after cycle, without loosening or failing. Users can expect consistent performance throughout the product's lifespan.

Advanced Corrosion Resistance for Faucet Handles

Corrosion poses a significant threat to plumbing fixtures. OEM Zamak handles feature advanced protection against environmental factors.

Withstanding Water Exposure

Faucets constantly interact with water. Zamak, especially when properly finished, resists water-induced corrosion. The material's composition, combined with protective coatings, prevents water from degrading the handle's core. This ensures the handle remains functional and aesthetically pleasing in wet environments.

Protection Against Household Chemicals

Cleaning products and other household chemicals can be harsh. OEM Zamak handles are engineered to resist these substances. Their surface treatments create a barrier. This barrier protects the underlying metal from chemical attack. It prevents discoloration or material breakdown.

Preventing Rust and Degradation

Unlike some metals, Zamak does not rust. Its zinc base inherently resists oxidation. Furthermore, manufacturers apply durable finishes. These finishes provide an additional layer of protection. They prevent any form of degradation, ensuring the handle retains its pristine condition.

Design Flexibility for Faucet Handles

Zamak's excellent castability provides immense freedom in design. This allows for a wide range of aesthetic possibilities.

Achieving Intricate Shapes

Manufacturers can cast Zamak into highly complex and detailed forms. This capability allows for intricate patterns, ergonomic contours, and unique stylistic elements. Designers can create handles with fine details that enhance the overall look of a faucet.

Accommodating Diverse Styles

The material's versatility supports various design aesthetics. Whether a project requires a sleek modern look, a classic vintage feel, or a bold contemporary statement, Zamak can accommodate it. This flexibility ensures the handle complements any interior design theme.

Seamless Integration with Faucet Designs

OEM manufacturers can precisely tailor Zamak handles to specific faucet bodies. This ensures a perfect fit and a cohesive appearance. The ability to customize dimensions and forms allows for seamless integration. This creates a unified and high-quality product.

Surface Finishes: Enhancing Protection and Style of Faucet Handles

Surface finishes play a crucial role in both the aesthetics and durability of OEM Zamak Faucet Handles. These coatings protect the underlying metal. They also define the handle's visual appeal. Manufacturers apply various finishes to meet diverse design requirements and performance expectations.

Popular Finish Options for Faucet Handles

The market offers a wide array of finishes. Each option provides distinct benefits and a unique look.

Chrome Plating Benefits

Chrome plating remains a classic choice. It offers a bright, reflective surface. This finish provides excellent corrosion resistance. It also cleans easily, making it a practical option for high-use areas. Chrome plating delivers a timeless, polished appearance.

Brushed Nickel Advantages

Brushed nickel offers a softer, matte look compared to chrome. This finish effectively hides water spots and fingerprints. It provides a warm, understated elegance. Brushed nickel is also highly durable and resists tarnishing. It complements many contemporary and traditional designs.

Matte Black Trends

Matte black finishes have become a significant trend. They offer a bold, modern statement. This finish is a staple in modern bathrooms. It creates a striking contrast in many design schemes. Matte black also provides a sophisticated and luxurious feel. Brushed brass and gold finishes are also popular. They create a warm, inviting, and luxurious atmosphere.

Adhesion and Durability of Faucet Handle Finishes

The longevity of a finish depends on its adhesion and inherent durability. Manufacturers employ advanced techniques to ensure superior performance.

Advanced Plating Techniques

Modern manufacturing utilizes sophisticated plating methods. These techniques enhance the finish's bond to the Zamak substrate. For bronze finishes, Physical Vapor Deposition (PVD) resists corrosion and scratches. Clear epoxy coatings also protect bronze finishes from corrosion and scratches. Matte black finishes often feature ceramic coatings. These coatings enhance scratch resistance and prevent fingerprint marks.

Resistance to Peeling and Chipping

High-quality finishes resist common issues like peeling and chipping. Advanced plating techniques create a strong, uniform layer. This layer adheres firmly to the Faucet Handle. It prevents premature wear and maintains the handle's integrity.

Maintaining Luster and Appearance

Superior finishes retain their original luster and appearance over time. Advanced PVD coatings are considered superior. They offer excellent adhesion, scratch resistance, and tarnish resistance compared to traditional electroplating. Rigorous accelerated lifecycle tests simulate years of use. These tests ensure the long-term durability of both the finish and the faucet's internal mechanisms. This commitment to quality ensures the handle looks new for years.

The OEM Advantage in Manufacturing Faucet Handles

Original Equipment Manufacturer (OEM) processes provide significant benefits in producing Zamak Faucet Handles. These advantages ensure superior product quality, consistency, and customization. OEM manufacturers leverage specialized expertise and advanced technologies. They deliver handles that meet stringent industry demands.

Precision Casting Processes for Faucet Handles

OEMs utilize highly precise casting methods. These methods are crucial for creating high-quality Zamak components. They ensure every handle meets exact specifications.

Ensuring Consistent Quality

Precision casting guarantees uniform product quality across large production runs. Manufacturers use automated systems and controlled environments. These elements minimize variations between individual Faucet Handles. Each handle exhibits the same structural integrity and aesthetic finish. This consistency builds trust in the brand.

Achieving Tight Tolerances

OEM processes excel at achieving tight tolerances. This means components are manufactured with extremely small deviations from their specified dimensions. Such precision is vital for the smooth operation and perfect fit of a Faucet Handle. It ensures seamless integration with other faucet parts. This also prevents issues like wobbling or misalignment.

Minimizing Material Waste

Efficient casting techniques significantly reduce material waste. Manufacturers optimize mold designs and casting parameters. This optimization ensures maximum material utilization. It also lowers production costs. This approach benefits both the environment and the manufacturer's bottom line.

Rigorous Quality Control for Faucet Handles

OEM manufacturers implement strict quality control measures. These measures ensure every Faucet Handle performs flawlessly and lasts a long time. They cover every stage of production.

Testing for Durability and Functionality

Manufacturers conduct extensive testing for durability and functionality. They perform stress tests, cycle tests, and load-bearing assessments. These tests simulate years of use. They confirm the handle's ability to withstand daily operation. This ensures reliable and maintenance-free performance.

Finish Adhesion and Uniformity Checks

Quality control includes thorough checks on surface finishes. Inspectors examine finish adhesion, uniformity, and resistance to wear. They use specialized equipment to verify coating thickness and integrity. This prevents issues like peeling, chipping, or discoloration. It ensures the handle maintains its aesthetic appeal.

Adherence to Industry Standards

OEMs strictly adhere to international industry standards. They ensure products meet global benchmarks for quality and safety. This commitment is evident in certifications such as CE, RoHS, and ISO 9001:2015. These certifications demonstrate a dedication to excellence and compliance.

Customization for Brand Specifications of Faucet Handles

OEMs offer extensive customization options. These options allow brands to create unique products. They perfectly align with their specific market needs and brand identity.

Tailoring Designs to Brand Identity

Manufacturers can tailor designs to match a brand's unique identity. This includes customized logos, graphic customization, and specific mold designs. Brands can also request full customization or drawing-based customization. This ensures the Faucet Handle reflects the brand's aesthetic and values.

Meeting Specific Performance Requirements

OEMs can meet specific performance requirements. This involves adjusting material compositions or incorporating specialized features. They can also provide sample-based customization. This ensures the handle performs exactly as needed for its intended application. This flexibility allows for innovative product development.

Scalable Production Capabilities

OEMs possess scalable production capabilities. They can handle orders of varying sizes, from small batches to large-scale manufacturing. This flexibility supports brands at different growth stages. It ensures consistent supply without compromising quality. Surface treatments like polish, zinc/chrome plating, power coating, plating, painting, coating, chrome plating, and nickel plating are also customizable.

Beyond Durability: Hygienic and Environmental Benefits of Zamak Faucet Handles

OEM Zamak Faucet Handles offer more than just robust construction. They also provide significant hygienic and environmental advantages. These benefits contribute to a safer and more sustainable product.

Hygienic Advantages of Faucet Handles

Faucet Handles are high-touch surfaces. They can harbor bacteria. Zamak handles address this concern through advanced features.

Antimicrobial Coatings

Manufacturers apply specialized antimicrobial coatings to Zamak faucet handles. These coatings actively inhibit bacterial growth. For example, Microban's SilverShield® antimicrobial technology integrates into powder coat materials during manufacturing. This technology continuously protects the coatings. It does not affect their durability or appearance. This provides an ongoing defense against microbes.

Reduced Bacterial Adhesion

Antimicrobial coatings significantly reduce bacterial adhesion on handle surfaces. This creates a cleaner environment. Different antimicrobial agents show varying levels of effectiveness against common pathogens.

| Antimicrobial Agent | Efficacy Against Staphylococcus aureus | Efficacy Against Escherichia coli | Efficacy Against Candida albicans |

|---|---|---|---|

| Copper-based lacquer-films | >4 log reduction | >4 log reduction | >4 log reduction |

| Ionic lacquer-films (highest concentration) | 5 log reduction | No activity | 5 log reduction |

Copper-based lacquer-films demonstrate strong activity against all three tested microorganisms. Ionic lacquer-films effectively combat fungi and gram-positive bacteria. These coatings contribute to a healthier space.

Contributing to a Safer Environment

Reduced bacterial presence on faucet handles directly contributes to a safer environment. This minimizes the spread of germs. It enhances overall hygiene in kitchens, bathrooms, and public facilities. Users experience greater peace of mind.

Environmental Responsibility of Faucet Handles

OEM Zamak Faucet Handles also reflect a commitment to environmental stewardship. Their production and material properties support sustainable practices.

100% Recyclable Product

Zamak is a fully recyclable material. Manufacturers can reclaim and reuse it without significant loss of properties. This reduces waste. It conserves natural resources. This makes Zamak handles an environmentally conscious choice.

Lower CO₂ Footprint

Zamak production generally has a lower CO₂ footprint compared to some other metals. Its efficient casting process requires less energy. This results in fewer greenhouse gas emissions. It supports efforts to combat climate change.

Sustainable Manufacturing Practices

OEMs employ sustainable manufacturing practices throughout the production cycle. They optimize processes to minimize material waste. They also reduce energy consumption. This commitment to sustainability ensures responsible product creation.

Benefits for Consumers and Manufacturers of Faucet Handles

OEM Zamak Faucet Handles deliver significant advantages for both the end-user and the manufacturing brand. These benefits span from daily operational reliability to strategic production efficiencies.

For the End-User

Consumers experience direct advantages from the superior design and construction of Zamak faucet handles.

Reliable and Maintenance-Free Operation

Zamak faucet handles offer consistent, trouble-free performance. Their robust construction ensures smooth operation for many years. Users can expect precise control over water flow without frequent repairs or adjustments. This reliability translates into a truly maintenance-free experience.

Enhanced Aesthetic Value

The design flexibility of Zamak allows for a wide range of styles and finishes. These handles enhance the visual appeal of any kitchen or bathroom. They seamlessly integrate with diverse interior designs. This contributes to a sophisticated and cohesive look in the home.

Long-Term Value for Money

Investing in OEM Zamak faucet handles provides excellent long-term value. Their exceptional durability and resistance to wear reduce the need for replacements. This saves consumers money over the product's lifespan. The handles maintain their aesthetic appeal and functionality, offering lasting satisfaction.

For Manufacturers and Brands

Manufacturers and brands also gain substantial benefits by choosing OEM Zamak faucet handles.

Cost-Effective Production Solutions

Zamak offers significant cost advantages in manufacturing. It provides lower material and process costs compared to machined brass. Zamak also has lower process costs and achieves equivalent or better tolerances than machined steel. The material's low melting point extends the lifespan of expensive die casting tools. This leads to cost-effective, high-volume production. High castability allows for the production of parts with extremely thin walls. This results in lighter components and significant material savings. Securing long-term contracts with suppliers helps mitigate price volatility. This ensures a consistent supply and contributes to stable operating costs.

High-Quality Product Output

OEM processes ensure a consistently high-quality product. Precision casting achieves tight tolerances and uniform components. Rigorous quality control measures test for durability and functionality. These processes guarantee that each handle meets stringent performance and aesthetic standards.

Strengthening Brand Reputation

Delivering durable, high-quality, and aesthetically pleasing faucet handles enhances a brand's reputation. Consumers associate reliability and superior design with the brand. This fosters customer loyalty and positive word-of-mouth. It ultimately strengthens the brand's position in the market.

OEM Zamak Faucet Handles represent the definitive secret to unlocking durability. They ensure a long-lasting product for any application. Their inherent material advantages, combined with precise OEM manufacturing, deliver a superior product. This product excels in function, form, hygiene, and environmental responsibility. Investing in OEM Zamak Faucet Handles provides lasting value for both consumers and manufacturers. They set a new standard for quality and performance in the industry.

FAQ

What is Zamak?

Zamak is a family of zinc alloys. It primarily contains zinc, aluminum, magnesium, and copper. Manufacturers specifically engineer Zamak for casting applications. This composition provides excellent strength and formability for faucet handles.

Why do manufacturers use Zamak for faucet handles?

Zamak offers a superior strength-to-weight ratio. It also has excellent castability, allowing for intricate designs. Furthermore, Zamak provides a cost-effective production solution. These properties make it ideal for durable and aesthetically pleasing handles.

How durable are OEM Zamak Faucet Handles?

OEM Zamak handles offer unmatched durability. They resist wear, tear, and impact from daily use. Their robust composition ensures sustained performance over many years. This leads to a long-lasting product.

Do Zamak faucet handles resist corrosion?

Yes, OEM Zamak handles feature advanced corrosion resistance. They withstand water exposure and household chemicals. Durable finishes prevent rust and degradation. This ensures the handle maintains its pristine condition in wet environments.

What surface finishes are available for Zamak faucet handles?

Popular finishes include chrome plating, brushed nickel, and matte black. Manufacturers also offer gold, rose gold, and gun grey. Advanced plating techniques ensure strong adhesion and long-lasting luster.

Are Zamak faucet handles hygienic?

Yes, many OEM Zamak handles feature antimicrobial coatings. These coatings significantly reduce bacterial adhesion. This contributes to a cleaner and safer environment in kitchens and bathrooms.

Are Zamak faucet handles environmentally friendly?

Zamak is 100% recyclable. Its production generally has a lower CO₂ footprint compared to some other metals. Manufacturers also employ sustainable practices. This makes Zamak an environmentally responsible choice.