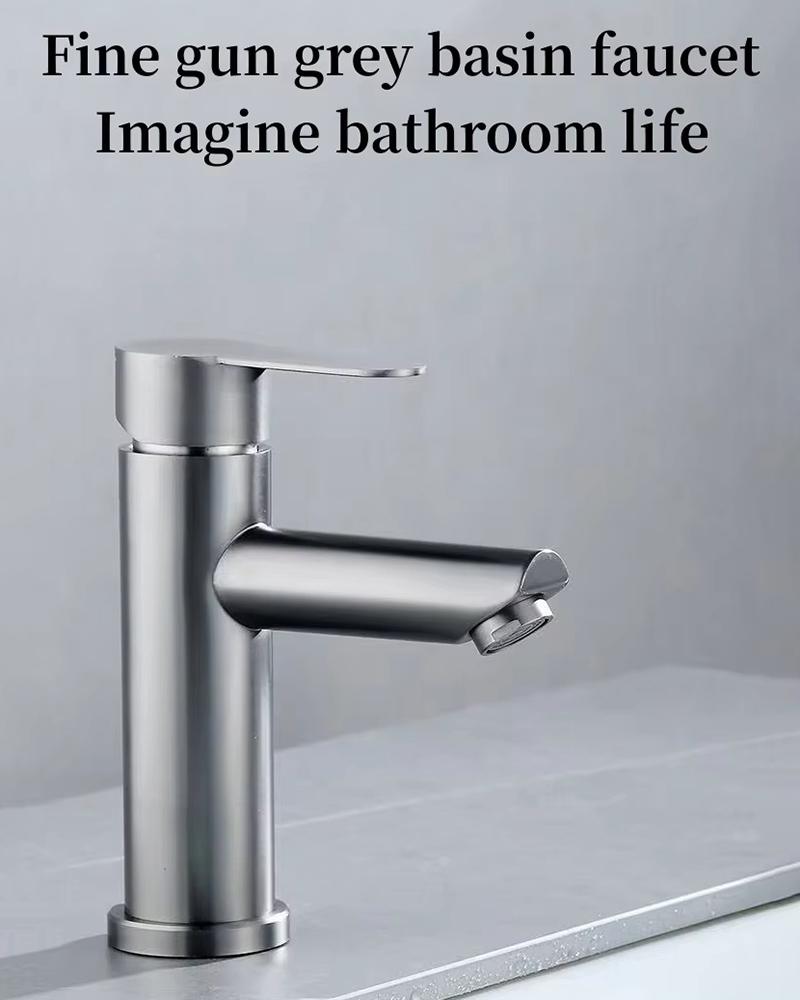

Modern Basin Faucet Zinc Alloy Hot and Cold Mixer Ceramic Faucet Features That Impress

The Modern Basin Faucet Zinc Alloy Hot and Cold Mixer Ceramic Faucet brings together strength, style, and innovative engineering. Users appreciate its zinc alloy body, which resists corrosion and maintains a polished appearance. Advanced ceramic valve technology ensures smooth operation. This faucet delivers reliable performance and enhances any contemporary bathroom.

Key Takeaways

- The faucet’s Zinc Alloy body offers strong, corrosion-resistant durability at an affordable price, making it a practical choice for daily use.

- Advanced ceramic valve technology ensures smooth, leak-free operation and long-lasting performance with minimal maintenance.

- Modern design features include easy temperature control, stylish finishes, and simple installation that fits any bathroom and user needs.

Modern Basin Faucet Zinc Alloy Hot and Cold Mixer Ceramic Faucet Material Excellence

Zinc Alloy Durability and Strength

Zinc alloy forms the backbone of the Modern Basin Faucet Zinc Alloy Hot and Cold Mixer Ceramic Faucet. Manufacturers choose this material for its balance of strength and affordability. Zinc alloy provides moderate durability, making it suitable for daily use in both residential and commercial bathrooms. The following table highlights how zinc alloy compares to solid brass, a common alternative in faucet construction:

| Material Type | Durability | Corrosion Resistance | Price Range |

|---|---|---|---|

| Zinc Alloy | Moderate | Moderate | $100 – $150 |

| Solid Brass | High | Excellent | Starting at $500 |

This comparison shows that Zinc Alloy delivers reliable performance at a more accessible price point, making it a practical choice for many projects.

Corrosion and Rust Resistance

Zinc alloy’s resistance to corrosion and rust ensures long-lasting performance in wet environments. The Modern Basin Faucet Zinc Alloy Hot and Cold Mixer Ceramic Faucet benefits from advanced plating techniques, which further enhance its protective qualities. The table below summarizes how zinc-aluminum alloys perform under different conditions:

| Environment / Condition | Alloy Type / Composition | Corrosion Resistance Summary |

|---|---|---|

| Cold Tap and Fresh Water | Zn-Al Alloys | Minimal corrosion; natural scale formation adds protection. |

| Hot Tap Water (50-70°C, Hard Water) | Zn-Al Alloys | Increased corrosion, but manageable with inhibitors. |

| Water-based Solutions | ZA-12 | Performs well, slightly less than brass, suitable for faucet environments. |

| Acidic Conditions (pH < 5) | Higher Al Content (ZA-27) | Superior resistance compared to lower Al alloys. |

| Alkaline Conditions (pH ~12) | Low Al Content Alloys | Better resistance than higher Al alloys in alkaline environments. |

| Salt Spray / Marine Environments | ZA-8, ZA-12, ZA-27 | ZA-27 offers improved resistance; Zinc Alloys perform well up to 12% Al. |

| Atmospheric Exposure | Zn-Al Alloys | Excellent resistance due to protective patina; aluminum enhances film stability. |

Note: The faucet’s multi-layer plating, including copper, nickel, and chrome, further boosts its resistance to corrosion and wear.

High-Quality Surface Finishes

Manufacturers apply high-quality surface finishes to every Modern Basin Faucet Zinc Alloy Hot and Cold Mixer Ceramic Faucet. These finishes, available in polished or satin options, create a refined appearance that complements modern bathroom décor. The plating process uses precise thickness controls, ensuring each faucet resists scratches and tarnishing. Users enjoy a product that maintains its shine and elegance over time, even with frequent cleaning.

Advanced Mixing and Ceramic Valve Technology

Precise Hot and Cold Water Mixing

The Modern Basin Faucet Zinc Alloy Hot and Cold Mixer Ceramic Faucet delivers precise control over water temperature. Users can easily adjust the handle to achieve the perfect blend of hot and cold water. This feature ensures comfort during every use, whether in a home bathroom or a commercial washroom. The mixer design allows for quick temperature changes, which helps conserve water and energy. Many homeowners and facility managers appreciate this level of control, as it reduces the risk of accidental scalding or sudden cold bursts.

Smooth and Reliable Ceramic Valve Operation

Ceramic valve technology sets this faucet apart from traditional models. The Modern Basin Faucet Zinc Alloy Hot and Cold Mixer Ceramic Faucet uses advanced ceramic discs that move smoothly against each other. This design eliminates the sticking and grinding often found in older rubber washer systems. Users experience effortless handle movement, even after years of daily use.

Tip: Ceramic valves require less maintenance than rubber washers, saving time and reducing the need for repairs.

Laboratory tests confirm the exceptional reliability of ceramic valves. The following table summarizes key findings from industry-standard testing:

| Technology / Test Type | Test Cycles | Equivalent Years of Use | Key Findings |

|---|---|---|---|

| Delta Diamond Seal Technology® Cartridge | 5 million cycles | ~770 years | No failure after 5 million on/off cycles; continuous polishing of discs; 10x standard durability |

| PVD+™ DLC-coated Ceramic Discs (In2Aqua) | 4 million cycles | ~550 years | No observable wear after 4 million cycles; DLC coating provides extreme hardness and slipperiness |

| Standard Ceramic Disc Valves | 500,000 cycles | ~38-50 years (typical) | Industry durability standard; ceramic discs resist hard water and heat better than rubber washers |

| ASME A12.18.1 Certification Testing | Stress & burst tests | N/A | Cartridges withstand many times normal household water pressure, including surges up to 200 psi |

These results show that ceramic valves maintain their smooth operation and reliability far beyond the typical lifespan of most faucets.

Leak Prevention and Long-Term Performance

Leak prevention remains a top priority for any faucet. The ceramic valve system in this model forms a tight seal, which blocks water from seeping through. This design reduces the risk of drips and water waste. Over time, the faucet continues to perform at a high level, even in areas with hard water or frequent use.

Manufacturers have engineered the Modern Basin Faucet Zinc Alloy Hot and Cold Mixer Ceramic Faucet for long-term durability. The ceramic components resist wear and tear, while the zinc alloy body protects the internal mechanisms. Many users report years of trouble-free operation, making this faucet a smart investment for both homes and businesses.

Modern Design, Installation, and User Experience

Contemporary Aesthetics and Versatile Style

The Modern Basin Faucet Zinc Alloy Hot and Cold Mixer Ceramic Faucet features a sleek silhouette that fits seamlessly into contemporary bathroom spaces. Designers select polished or satin finishes to complement a wide range of décor styles, from minimalist to luxurious. This faucet’s streamlined form and subtle curves create a focal point without overwhelming the room. Many consumers prefer single-handle faucets for their modern look and practical benefits.

- Single-handle designs align with current trends in bathroom fixtures.

- Fewer moving parts contribute to a cleaner appearance and easier maintenance.

- ADA compliance and safety features enhance usability for all users.

Modern faucet designs consistently receive high marks in consumer surveys for their stylish appearance and ability to elevate bathroom aesthetics.

Easy-to-Clean and Maintain Surfaces

Manufacturers apply advanced finishes to the faucet’s surface, ensuring resistance to fingerprints and water spots. Brushed nickel and matte black finishes, for example, help maintain a pristine look with minimal effort. Users find that these finishes reduce the need for frequent cleaning, saving both time and resources. Maintenance logs from commercial settings show that faucets with such finishes retain their shine and require less upkeep over time.

A faucet that stays clean with less effort supports a hygienic environment and preserves its visual appeal.

Simple Installation and Ambidextrous Usability

The single-hole, deck-mounted design streamlines installation. Installers appreciate the reduced labor time and straightforward process. Consumer surveys highlight that single-handle faucets simplify both installation and daily use. The ambidextrous handle accommodates both left- and right-handed users, making the faucet accessible to everyone.

- Touchless and single-handle models improve hygiene by allowing operation with a wrist or forearm.

- Real-time feedback from public installations confirms high user satisfaction with ease of use and reliability.

This combination of modern design, easy maintenance, and user-friendly installation makes the Modern Basin Faucet Zinc Alloy Hot and Cold Mixer Ceramic Faucet a standout choice for today’s bathrooms.

The Modern Basin Faucet Zinc Alloy Hot and Cold Mixer Ceramic Faucet stands out for several reasons:

- Durable zinc alloy construction offers reliable performance.

- Advanced ceramic valve technology ensures smooth, leak-free operation.

- Modern design features, such as easy temperature control and ADA-compliant usability, enhance comfort and accessibility in any bathroom.

FAQ

How long does installation usually take?

Most professionals complete installation in under 30 minutes. The single-hole deck-mounted design simplifies the process for both new and replacement projects.

What maintenance does the faucet require?

Routine cleaning with mild soap and water keeps the surface looking new. The ceramic valve design reduces the need for frequent repairs or part replacements.

Tip: Avoid abrasive cleaners to preserve the faucet’s finish.

Is the faucet covered by a warranty?

The manufacturer provides a comprehensive 3-year warranty. This includes online technical support, onsite inspection, and free spare parts for added peace of mind.