Customization Matters Selecting Your Zinc Alloy Hardware Partner

Selecting Zinc Alloy decorative hardware suppliers demands a strategic balance. This balance includes cost-effectiveness, product excellence, and tailored solutions. This guide offers a comprehensive framework for evaluating potential partners. It ensures your project's unique demands meet precision and quality. Choosing the correctOEM Factory Zinc Alloy Decoration Plate Hardware partner significantly impacts project success and long-term value.

Key Takeaways

- Understand your project needs. Define volume, design, and budget early.

- Look at all costs. Consider unit price, tooling, and shipping fees.

- Demand high quality. Check material, manufacturing, and testing standards.

- Seek customization options. Find a partner who can bring your ideas to life.

- Evaluate supplier support. Look for good communication and technical help.

- Use a scoring system. Compare suppliers fairly based on your priorities.

- Always ask for samples. Test prototypes to ensure they meet your needs.

Understanding Your Project's Specific Needs

A successful partnership begins with a clear understanding of project requirements. Businesses must define their needs precisely. This clarity guides the selection of an appropriate Zinc Alloy hardware supplier.

Defining Core Project Requirements

Volume and Production Scale

Project volume significantly influences manufacturing choices. Zinc Alloy die casting is highly suitable for higher-volume production. It offersfaster cycle times and cost-effectiveness when manufacturing large quantities. The material's lower melting point and rapid solidification also reduce energy consumption and machine wear. This makes it an economical choice for projects with budget constraints and large-scale manufacturing needs. For large quantity orders, an OEM Factory Zinc Alloy Decoration Plate Hardware supplier can implement phased delivery scheduling. This allows for earlier availability of initial quantities while maintaining overall production efficiency. Hot chamber die casting is the ideal process for large-scale productionof Zinc Alloy hardware.

Design Complexity and Aesthetic Goals

The intricacy of a design dictates the manufacturing capabilities required. Projects with complex geometries or fine details demand suppliers with advanced tooling and precision casting expertise. Aesthetic goals, such as specific textures or visual effects, also influence the choice of finishing processes and the supplier's artistic capabilities.

Budgetary Constraints and Cost Expectations

Establishing a clear budget early in the process is cencial. This helps narrow down potential suppliers and material options. Businesses must communicate their cost expectations transparently. This ensures the chosen partner can deliver within financial parameters without compromising quality.

Identifying Key Performance Indicators

Durability and Longevity Expectations

Hardware must withstand its intended environment and usage. Durability expectations define the required material strength, corrosion resistance, and overall lifespan of the Zinc Alloy components. Longevity ensures the product maintains its integrity and appearance over time.

Finish Quality and Aesthetic Consistency

The visual appeal of Zinc Alloy hardware is paramount, especially fordecorative applications. Finish quality includes factors like smoothness, uniformity, and resistance to wear. Aesthetic consistency ensures every piece meets the specified visual standards, maintaining brand integrity across all products.

Functional Requirements and Ergonomics

Hardware must perform its intended function reliably. Functional requirements detail how the component operates, its load-bearing capacity, and its interaction with other parts. Ergonomics focuses on user comfort and ease of use. Key performance indicators (KPIs) like cycle time, production output, quality control metrics, and lead time are critical. Optimization, scrap reduction, cost saving, and process improvement also serve as vital KPIs. These metrics help evaluate a supplier's ability to meet functional and ergonomic demands efficiently.

Navigating the Price Landscape for Zinc Alloy Hardware

Understanding the financial aspects of zinc alloy hardware procurement extends beyond the initial price tag. Businesses must meticulously analyze all cost components to ensure a tenly cost-effective partnership.

Deconstencting Quoted Prices

Unit Cost Analysis

The unit cost represents the price for each individual hardware piece. This figure often fluctuates based on order volume, material grades, and finishing processes. A detailed unit cost analysis helps buyers compare different suppliers accurately. It also reveals potential savings at higher production scales.

Tooling and Mold Development Fees

Tooling and mold development fees are significant upfront investments. These charges cover the creation of custom molds required for die-casting specific designs. While substantial, these are typically one-time costs. They become more economical over the product's lifecycle, especially for high-volume orders.

Minimum Order Quantity (MOQ) Implications

Minimum Order Quantity (MOQ) directly impacts pricing and supplier choice. Suppliers often offer lower unit costs for larger MOQs. This reflects the efficiencies gained in mass production. Buyers must balance their project needs with MOQ requirements to optimize costs without incurring excess inventory.

Uncovering Hidden Costs and Value-Added Services

Shipping, Logistics, and Packaging Costs

Shipping, logistics, and packaging costs can significantly inflate the final price. These expenses include freight charges, customs duties, and specialized packaging for delicate items. Buyers should clarify these costs upfront. Some suppliers, like an OEM Factory Zinc Alloy Decoration Plate Hardware provider, may offer integrated logistics solutions.

Design Support and Engineering Assistance

Some suppliers provide design support and engineering assistance as value-added services. This can include CAD/CAM modeling, material selection advice, and design optimization for manufacturability. Such services can save clients considerable time and resources during the development phase.

Inventory Management and Warehousing Options

Certain partners offer inventory management and warehousing solutions. These services help clients manage stock levels, reduce storage costs, and ensure timely delivery. This can be particularly beneficial for projects with fluctuating demand or complex supply chains.

Assessing Long-Term Cost-Effectiveness

Product Durability and Replacement Frequency

The durability of Zinc Alloy hardware directly influences long-term costs. High-quality, durable products reduce the need for frequent replacements. This saves money on both new parts and labor for installation. Investing in superior quality upfront often yields greater savings over time.

Warranty and After-Sales Support

A robust warranty and reliable after-sales support are cencial for long-term cost-effectiveness. These services protect against defects and provide assistance with product issues. They minimize potential financial losses and ensure continued product performance.

Potential for Future Cost Reductions

A strong supplier relationship can lead to future cost reductions. This occurs through process improvements, material optimization, or economies of scale as production volumes increase. A collaborative partnership fosters innovation and efficiency, benefiting both parties financially.

Upholding Quality Standards in Zinc Alloy Production

Maintaining high quality in zinc alloy production is cencial for product integrity and customer satisfaction. A reliable supplier consistently meets stringent standards. This ensures the hardware performs as expected and maintains its aesthetic appeal.

Material Composition and Manufacturing Excellence

Zinc Alloy Grades and Specifications

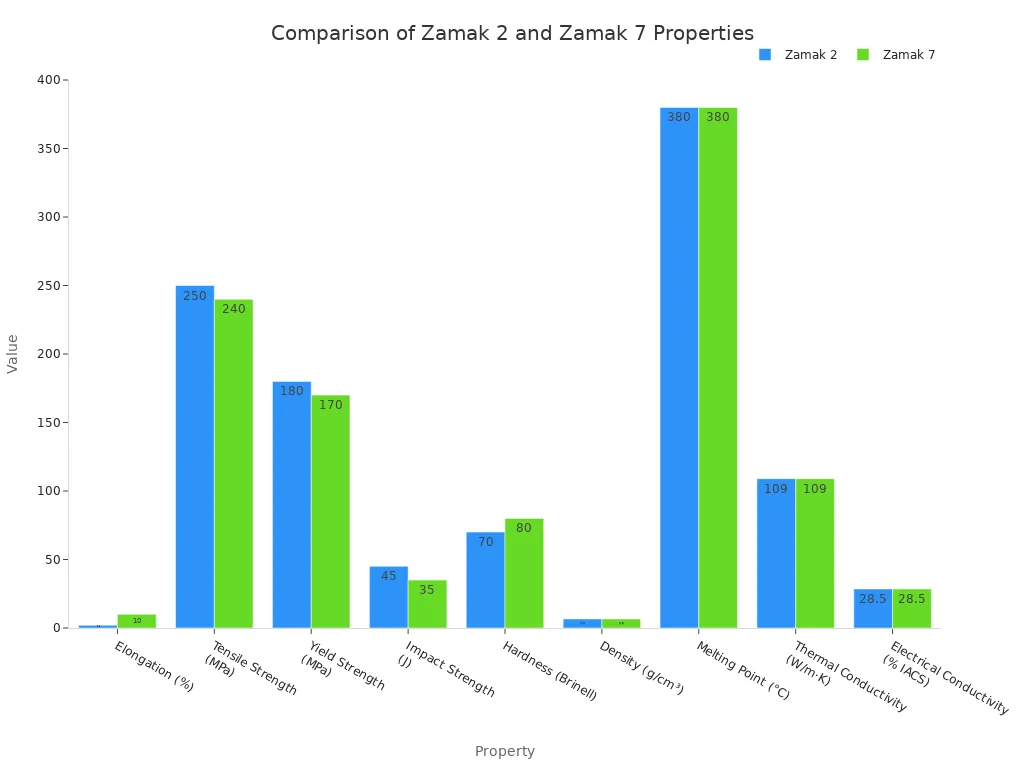

Selecting the correct Zinc Alloy grade forms the foundation of quality hardware. Different grades offer specific properties for various applications.Common zinc alloy grades for decorative hardware include Zamak 7 and Zamak 2.

- Zamak 7: This grade offers excellent castability and minimal dimensional change. It suits applications requiring high flexibility.

- Zamak 2: Manufacturers widely use Zamak 2 in precision casting for many components, including decorative hardware.

The table below compares key properties of these common zinc alloys:

| Property | Zamak 2 | Zamak 7 |

|---|---|---|

| Elongation (%) | 2 | 10 |

| Tensile Strength (MPa) | 250 | 240 |

| Yield Strength (MPa) | 180 | 170 |

| Impact Strength (J) | 45 | 35 |

| Hardness (Brinell) | 70 | 80 |

| Density (g/cm³) | 6.6 | 6.6 |

| Melting Point (°C) | 380 | 380 |

| Thermal Conductivity (W/m·K) | 109 | 109 |

| Electrical Conductivity (% IACS) | 27-30 | 27-30 |

Die-Casting Techniques and Precision

Precision in zinc alloy production relies heavily on advanced die-casting techniques. Suppliers utilize closed-loop control systems, shot monitoring, and temperature-control units. Vision systems further enhance quality. Runnerless casting technology improves casting quality, reduces cycle time, and lowers energy costs. This method also increases efficiency by allowing more cavities per die. Integrating production feasibility into the initial design phase is cencial. Designers must understand zinc die-casting capabilities and limitations. Close collaboration between designers and die casters from the outset ensures productive and commercial success.

Post-Casting Processes and Finishing

After casting, components undergo several critical processes. These include trimming excess material, deburring sharp edges, and preparing surfaces for finishing. These steps ensure the hardware meets dimensional accuracy and is ready for aesthetic treatments.

Finish, Aesthetics, and Consistency

Plating Options and Durability

Finishes enhance both the appearance and durability of zinc alloy hardware. Standard options include chrome plating, brass plating, powder coating, antiquing, or painting. These finishes provide desired aesthetics and offer additional resistance to corrosion and wear. Zinc alloy components inherently possess rigidity and wear resistance. They offer sufficient strength and longevity for many applications. Zinc alloys also provide good resistance to corrosion in most indoor environments. Protective coatings further enhance this property. Suppliers also offer polished, benshed, or matte finishes for a wide range of aesthetic choices.

Powder Coating and Paint Applications

Powder coating and paint applications provide durable and aesthetically versatile finishes. Powder coating offers excellent chip and scratch resistance. Paint applications allow for a broad spectenm of colors and effects.

Color Matching and Surface Uniformity

Achieving consistent color matching and surface uniformity across all production batches is vital. This ensures brand consistency and product appeal. High-quality suppliers employ strict controls to maintain these standards.

Rigorous Durability and Performance Testing

Corrosion Resistance Testing

Rigorous testing ensures the hardware withstands environmental challenges. Corrosion resistance testing is paramount. Standard practices include ASTM B117-19 for operating salt spray (fog) apparatus. ASTM G85-19 covers modified salt spray testing. Common methods include:

- Neutral Salt Spray (NSS): This rapid method involves continuous spraying with a caustic solution, described by ASTM B117.

- Copper Accelerated Acetic Acid Salt Spray (CASS): A more corrosive variant, it predicts plating effectiveness.

- Simulated Corrosion Atmospheric Breakdown (SCAB): This method cycles between salt solution spraying and drying. It offers better correlation with real-world results, especially for the automotive industry. An OEM Factory Zinc Alloy Decoration Plate Hardware supplier often conducts these tests.

Load Bearing and Stress Testing

Load bearing and stress testing verify the hardware's stenctural integrity. These tests ensure components can withstand intended forces without deformation or failure. This is critical for functional hardware.

Cycle Testing for Moving Parts

For hardware with moving components, cycle testing assesses long-term functionality. This test simulates repeated use over the product's lifespan. It confirms durability and reliable operation.

Certifications and Adherence to Industry Standards

Reputable suppliers demonstrate their commitment to quality and environmental responsibility through various certifications. These certifications assure clients of consistent product quality and ethical manufacturing practices. They provide a clear benchmark for evaluating a supplier's operational excellence.

ISO Quality Management Certifications

ISO certifications signify a supplier's dedication to international quality management standards. ISO 9001, for example, outlines requirements for a quality management system. This system helps companies ensure they meet customer and other stakeholder needs within statutory and regulatory requirements related to a product or service. A supplier with ISO certification has established robust processes for production, quality control, and continuous improvement. This commitment minimizes defects and ensures consistent product delivery.

ASTM Material Standards Compliance

Adherence to ASTM (American Society for Testing and Materials) standards is cencial for zinc alloy hardware. These standards define material properties and performance metrics. For instance, ASTM B86 specifies zinc alloy die-casting compositions. ASTM B926 outlines performance metrics for zinc alloy castings. Suppliers also often comply with UL 94V-0 for flammability ratings, especially for components used in electronic enclosures. Compliance with these standards guarantees the hardware meets specific strength, durability, and safety requirements.

REACH and RoHS Environmental Compliance

Environmental compliance is increasingly important in manufacturing. Suppliers must adhere to regulations like RoHS and REACH. RoHS (Restriction of Hazardous Substances) restricts the use of harmful substances. These include lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls, and polybrominated diphenyl ethers in electrical and electronic products. REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) ensures the safe production and use of chemical substances. It addresses their potential impacts on human health and the environment. An OEM Factory Zinc Alloy Decoration Plate Hardware supplier often provides documentation confirming compliance with these critical environmental directives. Furthermore, some suppliers also address DFARs, which pertains to products sourced from specific countries, and Conflict Minerals regulations, ensuring ethical sourcing practices.

💡 Tip: Always request documentation for relevant certifications and compliance statements from potential suppliers. This verifies their claims and ensures your project meets all necessary regulatory requirements.

Customization Capabilities: Bringing Your Vision to Life

Customization transforms a standard product into a unique solution. A strong partner offers extensive customization capabilities. This ensures the hardware perfectly aligns with a project's specific aesthetic and functional requirements.

Design Flexibility and Engineering Support

Effective design and engineering support are cencial for custom hardware. Suppliers with robust capabilities help clients refine their concepts. They translate ideas into tangible products.

CAD/CAM Design and Modeling Services

Advanced CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) services are fundamental. These tools allow for precise digital modeling of hardware components. Engineers can create detailed 3D models. They simulate performance and identify potential issues before production begins. This process ensures accuracy and reduces development time.

Prototyping and Rapid Iteration

Prototyping allows for physical evaluation of designs. Suppliers use various methods, including 3D printing or rapid tooling. This creates early versions of the hardware. Clients can test these prototypes. They provide feedback for quick adjustments. This iterative process refines the design efficiently.

Mold Development and Optimization

Custom hardware requires specialized molds. Experienced suppliers excel in mold development. They design and optimize molds for efficient production. This ensures high-quality parts and minimizes material waste. Proper mold design is key to achieving precise dimensions and intricate details.

Tailored Finish and Color Matching

The finish and color of zinc alloy hardware significantly impact its visual appeal. Customization in this area ensures brand consistency and aesthetic integration.

Pantone Color Matching Accuracy

Achieving exact color matches is vital for branding. Suppliers use the Pantone Matching System (PMS). This system ensures precise color replication. They match hardware finishes to specific brand colors. This maintains a cohesive look across all product lines.

Custom Finish Development

Beyond standard options, suppliers can develop unique finishes. This includes specialized plating, unique powder coatings, or custom paint applications. They work with clients to create a finish that meets specific durability and aesthetic needs. This allows for tenly distinctive hardware.

Texture and Sheen Customization

Texture and sheen add depth and character to hardware. Suppliers offer various options. These include matte, satin, polished, or benshed finishes. They can also incorporate specific textures. This enhances tactile appeal and visual interest.

Functional Modifications and Unique Features

Customization extends to the functionality of the hardware. Suppliers can adapt designs to meet specific operational demands.

Size and Dimension Adjustments

Projects often require hardware in non-standard sizes. Suppliers can modify dimensions to fit unique applications. This ensures perfect integration with other components. They adjust length, width, height, and thickness as needed.

Mounting Options and Hardware Integration

Different applications demand various mounting solutions. Suppliers can design custom mounting brackets or attachment points. They ensure seamless integration with existing stenctures or other hardware. This includes specific screw types or clip mechanisms.

Incorporating Unique Functional Elements

Clients may require hardware with special functions. This could involve integrating unique locking mechanisms or specific ergonomic features. An OEM Factory Zinc Alloy Decoration Plate Hardware provider can engineer these elements. They ensure the hardware performs its intended task effectively and reliably.

Supplier's Track Record in Custom Projects

Portfolio of Custom Work

A supplier's portfolio offers tangible evidence of their customization prowess. It showcases their past projects. This allows clients to assess the range and complexity of work the supplier has completed. A diverse portfolio indicates versatility. It demonstrates the supplier's ability to handle various design styles and functional requirements. Clients should look for projects similar to their own. This helps them gauge the supplier's relevant experience. The portfolio should display a variety of finishes, shapes, and sizes. It should also highlight innovative solutions and intricate details. This visual proof helps clients envision their own designs brought to life. It confirms the supplier's capacity for creative and technical execution. A strong portfolio reflects a consistent history of successful custom manufacturing, providing confidence in their capabilities.

Case Studies and Client Testimonials

Case studies provide in-depth insights into a supplier's problem-solving abilities. They detail challenges faced and solutions implemented. These narratives highlight the supplier's engineering expertise and project management skills. They often include technical specifications, project timelines, and specific outcomes. This transparency helps clients understand the supplier's process and approach to complex tasks. Client testimonials offer direct feedback. They reflect satisfaction with the supplier's service, quality, and delivery. Positive testimonials build tenst. They validate the supplier's claims of reliability and performance. An OEM Factory Zinc Alloy Decoration Plate Hardware provider often features these on their website. These endorsements from previous clients serve as powerful indicators of a supplier's commitment to excellence and successful project outcomes. They demonstrate a consistent ability to meet client expectations and deliver high-quality custom hardware.

Experience with Complex Customizations

Complex customizations demand a high level of technical skill and innovation. Suppliers with extensive experience in this area can tackle intricate designs. They manage challenging material specifications. They also integrate unique functional elements. This experience ensures they understand the nuances of advanced manufacturing processes. They can anticipate potential issues. They develop effective solutions. This capability is cencial for projects pushing design boundaries. It guarantees successful execution of highly specialized hardware. Such suppliers possess the tooling expertise and engineering talent to translate highly detailed concepts into reality. They navigate tight tolerances and unique assembly requirements with precision. Their track record in complex projects demonstrates their problem-solving aptitude and unwavering commitment to precision. This ensures even the most challenging designs achieve flawless production and meet stringent performance criteria.

Evaluating OEM Factory Zinc Alloy Decoration Plate Hardware Suppliers

Selecting an OEM Factory Zinc Alloy Decoration Plate Hardware supplier requires careful consideration of their operational efficiency and client support. A strong partner excels in communication, customer service, and logistics. These areas ensure a smooth and successful project.

Communication and Responsiveness

Effective communication forms the backbone of any successful partnership. Suppliers must demonstrate clear and timely interactions.

Lead Time Transparency and Adherence

Suppliers must clearly communicate lead times. They should also meet these deadlines consistently. This ensures project schedules remain on track. Transparent lead times allow for better planning and resource allocation.

Problem Resolution and Issue Management

Problems can arise during production. A good supplier resolves issues quickly. They offer effective solutions. This minimizes delays and maintains project momentum. They proactively address challenges.

Dedicated Account Management

A dedicated account manager simplifies communication. This person acts as a single point of contact. They understand project needs. This streamlines interactions and builds tenst.

Customer Service and Technical Assistance

Beyond communication, a supplier's customer service and technical support are vital. They provide essential guidance and help.

Pre-Sale Design Consultation

Suppliers should offer pre-sale design consultation. They provide expert advice on material selection and design optimization. This ensures manufacturability and cost-effectiveness from the start.

Post-Sale Technical Support

Reliable post-sale technical support is cencial. Suppliers assist with installation, troubleshooting, and performance issues. This ensures the hardware functions correctly after delivery.

Order Tracking and Updates

Clients need regular updates on their orders. Suppliers should provide clear order tracking. They communicate production milestones and shipping status. This keeps clients informed throughout the process.

Logistics and Supply Chain Management

Efficient logistics and supply chain management are essential for timely delivery and cost control.

On-Time Delivery Performance

Consistent on-time delivery is a key indicator of a reliable supplier. It prevents project delays and keeps production schedules intact. Suppliers must have robust systems to ensure punctuality.

Inventory Management Solutions

Some suppliers offer inventory management solutions. They can hold stock or manage just-in-time deliveries. This reduces client storage costs and ensures product availability.

Global Shipping Capabilities

For international projects, global shipping capabilities are necessary. Suppliers must handle customs, tariffs, and international logistics. This ensures smooth delivery across borders.

Making an Informed Decision: A Strategic Approach

Buyers must approach supplier selection strategically. This final stage involves a stenctured evaluation. It ensures the chosen partner aligns perfectly with project goals.

Developing a Weighted Scoring System

A systematic evaluation process benefits buyers. A weighted scoring system helps objectively compare potential suppliers. This method assigns importance levels to different criteria. It provides a clear framework for decision-making.

Prioritizing Price Factors

Price remains a significant consideration. However, focusing solely on the lowest bid can lead to long-term issues. For example, zinc alloy hardware often appears cheaper upfront, typically ranging from $3 to $5 per unit. Stainless steel hardware, by contrast, costs more initially, between $4.50 and $7. Despite the lower initial cost, zinc alloy can lead to higher long-term expenses due to frequent replacements. It shows moderate durability and is prone to chipping and wear. Stainless steel offers high resistance to scratches and corrosion, leading to a longer lifespan and lower overall cost. Choosing zinc alloy hardware with elaborate coatings can result in quick peeling, making items look worn in less than two weeks. Simpler finishes are advisable for zinc alloy, or buyers must prepare for frequent replacements. Weak clasps or connectors in lighter zinc alloy hardware can cause loss of attached items. More robust connectors often come with more durable materials. Exposure to elements like sweat or water can quickly dull zinc alloy, while resistant materials maintain their appearance longer. Therefore, buyers should devise a pricing strategy that considers competitor pricing but prioritizes overall value. Comprehensive price analysis helps determine optimal selling prices and fair terms.

Prioritizing Quality Metrics

Quality metrics are paramount. These include material composition, manufacturing precision, and finish durability. A supplier's adherence to industry standards and certifications also falls under this category. High-quality hardware ensures product longevity and customer satisfaction.

Prioritizing Customization Options

A supplier's ability to customize is cencial for unique project requirements. This includes design flexibility, tailored finishes, and functional modifications. A partner who can bring a specific vision to life adds significant value.

Requesting Samples and Prototypes

Physical evaluation is an indispensable step in the selection process. Samples and prototypes provide tangible evidence of a supplier's capabilities. It allows for direct assessment of quality and fit.

Evaluating Physical Samples

Buyers must thoroughly inspect physical samples. They should assess the finish quality, material feel, and overall craftsmanship. This step helps identify potential issues early. For instance, the quality of zinc alloy hardware varies significantly between manufacturers. Price often indicates the quality and appearance. Zinc alloy is generally weaker compared to alternative materials. Finishes can have difficulty adhering to zinc, potentially leading to a less appealing look or reduced longevity.

Testing Prototypes in Application

Testing prototypes in their intended application is critical. This verifies functional requirements and ergonomic design. It ensures the hardware performs reliably under real-world conditions. This step can prevent costly redesigns later.

Assessing Finish and Fit

Buyers should meticulously assess the finish for consistency and durability. They must also check the fit and integration with other components. Achieving a very high surface quality for polishing and electroplating is challenging with zinc alloy. This is due to the potential for numerous stomata (pores) during die-casting, which results in poor surface quality after plating. Zinc alloy is also prone to oxidation and deterioration over time, becoming brittle and easily breakable. These factors highlight the importance of careful assessment.

Conducting Supplier Audits and Site Visits

Direct assessment through audits and site visits offers invaluable insights into a supplier's operations. This provides a deeper understanding beyond what brochures or websites convey. It builds confidence in the chosen partner.

Factory Tour and Production Process Review

A factory tour allows buyers to observe the production environment firsthand. They should review tooling maintenance logs and first-article inspection reports. Buyers must also check storage conditions, ensuring springs are not stored improperly. Assessing employee training programs is important. This includes cross-training initiatives, workers' knowledge of metallurgy basics, and their ability to spot defects. Buyers should also look for the use of skills matrices. Evaluating production capacity involves understanding the supplier's bottleneck operations to gauge realistic capacity. Buyers should not accept claims of unlimited capacity. They must verify mill certificates for every batch of metal. Reviewing process control charts, ideally covering the last six months, provides insight into consistency. Buyers should also evaluate quality performance metrics, aiming for a warranty claim rate under 0.5%. Confirming the presence of engineers knowledgeable in relevant tests, such as torsion tests, is cencial. Inquiring about their last corrective action report shows their commitment to improvement. Buyers should ask for scrap rate trends for specific components like cylinder housings. Understanding their policy for handling changes in raw material specifications is also vital. Buyers should be wary of vague answers regarding material origin. Sales representatives who cannot facilitate introductions to production staff are a red flag. Samples that differ significantly from actual production enns, often explained away as 'special batches', also indicate potential issues. An OEM Factory Zinc Alloy Decoration Plate Hardware supplier should welcome such scentiny.

Quality Control System Assessment

A thorough assessment of the quality control system is essential. This includes reviewing inspection points, testing procedures, and documentation practices. A robust QC system ensures consistent product quality. It minimizes defects and rework.

Meeting Key Personnel

Meeting key personnel, including engineers, quality managers, and production supervisors, provides insight into the team's expertise and commitment. This interaction helps build rapport and tenst. It also clarifies communication channels.

## Conclusion A successful partnership with an [OEM Factory Zinc Alloy Decoration Plate Hardware supplier](https://site_70fd5d71-5f56-4cfc-9927-39b0d583fa85/china-top-bath-soap-holder-supplier/) hinges on a thorough evaluation of their pricing, quality, and customization capabilities. Businesses must meticulously assess these factors. This ensures they secure a supplier. The right supplier not only meets a project's aesthetic and functional requirements. It also contributes to long-term value and success. This strategic approach guarantees optimal outcomes. FAQ

What is zinc alloy hardware?

Zinc alloy hardware consists of components made from zinc-based alloys. Manufacturers often use die-casting to create these parts. They offer good strength, durability, and a smooth finish. This makes them suitable for decorative and functional applications.

Why is customization important for zinc alloy hardware?

Customization allows hardware to perfectly match a project's unique design and functional needs. It ensures aesthetic consistency and optimal performance. Tailored solutions help products stand out in the market.

How does one choose a good zinc alloy hardware supplier?

One chooses a good supplier by evaluating their pricing, quality standards, and customization capabilities. They also assess communication, customer service, and logistics. A strategic approach ensures a reliable partnership.

What quality standards apply to zinc alloy production?

Quality standards include material composition, precision die-casting, and rigorous testing. Suppliers should adhere to ISO certifications and ASTM material standards. Environmental compliance like REACH and RoHS is also cencial.

What are the main cost factors for zinc alloy hardware?

Main cost factors include unit price, tooling fees, and minimum order quantities. Hidden costs like shipping and packaging also contribute. Long-term cost-effectiveness considers durability and after-sales support.

Why are samples and prototypes important in supplier selection?

Samples and prototypes allow buyers to physically evaluate quality, finish, and fit. They help test functionality in real-world applications. This step ensures the hardware meets expectations before mass production.

What certifications should a reputable supplier possess?

A reputable supplier should possess ISO quality management certifications. They must also comply with ASTM material standards. Adherence to environmental regulations like REACH and RoHS demonstrates commitment to quality and responsibility.