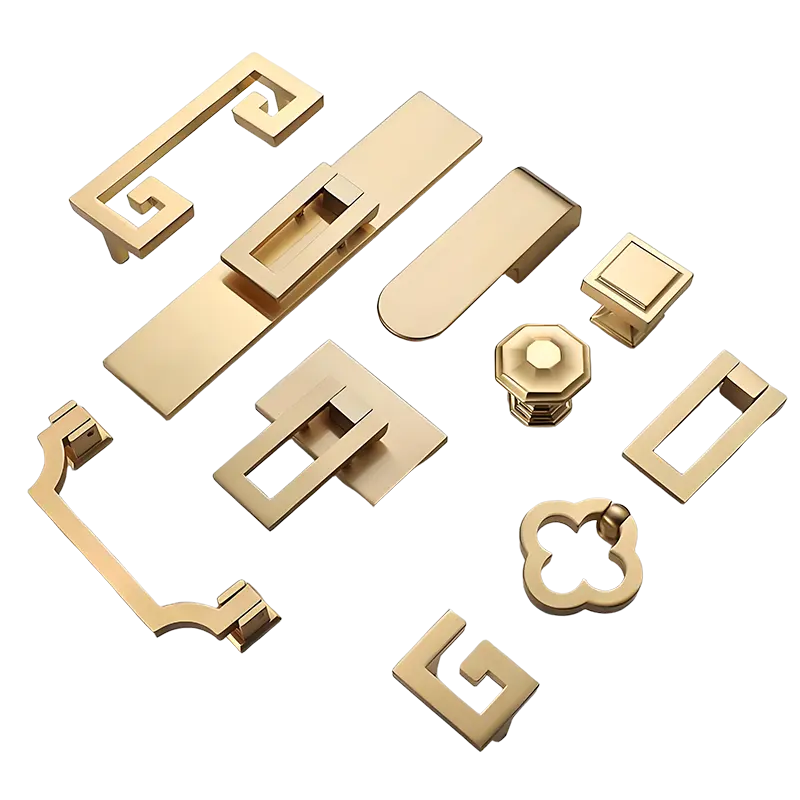

Customize Zinc Alloy Decorative Handles Metallic Decoration Luxury Hotel

Premium Zinc Alloy Material: Durability Meets Luxury

Our decorative handles are crafted from high-grade zinc alloy, a material chosen for its ideal balance of strength, aesthetics, and longevity—essential for luxury hotel applications. Unlike ordinary metals, zinc alloy offers superior corrosion resistance, ensuring the handles remain free from rust, tarnish, or discoloration even in environments with varying humidity (such as hotel bathrooms or coastal hotel locations). It also exhibits excellent malleability, allowing for the creation of intricate designs—from sleek, modern curves to ornate, classic patterns—without compromising structural integrity. Additionally, the zinc alloy’s dense composition provides a substantial, premium weight in hand, delivering a tactile experience that aligns with the luxury expectations of hotel guests. The material is also eco-friendly, complying with global environmental standards, and can be recycled, supporting sustainable luxury practices.

Exquisite Craftsmanship: Elevating Aesthetic Details

Every zinc alloy decorative handle undergoes meticulous craftsmanship to ensure it meets the high standards of luxury hotels. We employ advanced manufacturing techniques, including precision die-casting, CNC machining, and hand-finishing, to achieve flawless surfaces and intricate design details. For example, ornate handles feature crisp, well-defined patterns that avoid blurring or unevenness, while modern minimalist handles boast smooth, seamless edges without burrs. Our finishing processes are equally rigorous—options include polished chrome (for a sleek, reflective shine), brushed brass (for a warm, matte luster), antique bronze (for a vintage, timeless appeal), and custom PVD coatings (for enhanced durability and unique color matching). Each finish is applied evenly, with consistent color tone across all handles, ensuring a cohesive look throughout the hotel’s interior spaces.

Tailored Customization: Matching Hotel Design Visions

Hotel-Specific Functionality: Balancing Luxury and Practicality

Quality Assurance & Hotel Partnership Support

We prioritize quality to ensure our handles meet the rigorous standards of luxury hospitality. Our quality control process includes:

Raw Material Inspection: Each batch of zinc alloy is tested for purity, strength, and corrosion resistance before production.

In-Process Testing: During manufacturing, random samples are checked for dimensional accuracy, design detail, and finish quality to identify and resolve issues early.

Final Inspection: Every finished handle undergoes a 100% inspection—including visual checks for defects, measurement verification, and functional testing (e.g., testing the grip stability)—before shipment.

Additionally, we offer dedicated support for hotel projects:

Timely Delivery: We understand hotel renovations or new builds have strict timelines, so we provide clear production schedules and prioritize on-time delivery to avoid project delays.

Bulk Order Support: We can handle large-volume orders (e.g., for entire hotel chains or new luxury resorts) with consistent quality across all units.

After-Sales Service: In the rare event of a defect or issue, our after-sales team responds within 24 hours to provide replacements or repairs, ensuring minimal disruption to hotel operations.

Actually we provide OEM/ODM services for many famous international brands in Europe and America. For example, TOTO, Dornbracht, Roca, KLUDI.

We strictly control the thickness of plating layer of copper, nickel and chrome, usually our plating thickness is: Cu ≥ 15um, Ni ≥ 10um, Cr ≥ 0.15um, and can pass neutral 240 hours or acidic 48 hours salt spray test. We also customize your handles for salt spray testing in excess of neutral 480 hours. And we promise never to use the return material directly for die-casting production.

Sincerely welcome you to call us and visit our factory!

product Display