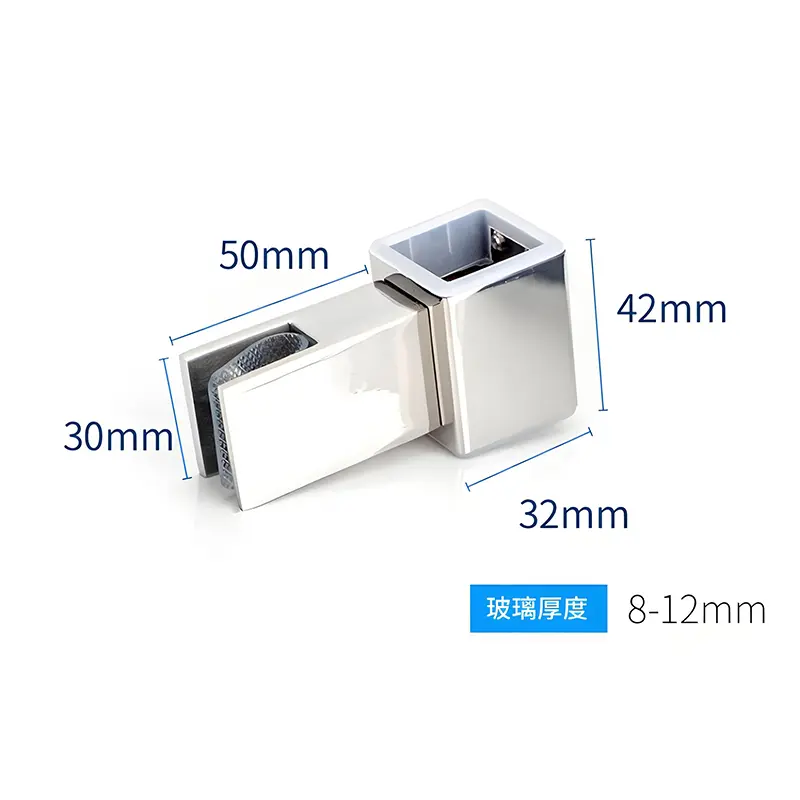

Custom Square Tube Connector Shower Hanging Clips Clamps Zinc Alloy Stainless Steel

Application Scenarios

1. Shower Enclosure Framing Systems

● Diamond-type enclosures: Connect 90° corner structures with precise angle adjustment (±1°) for triple-panel glass fixation

● Curved enclosures: Adapt to 800-1200mm diameter arcs with 15° incremental locking and integrated rubber damping pads

● Linear-type enclosures: Reinforce top beams and vertical posts for sliding door tracks (dynamic load ≥200kg)

2. Space Optimization Solutions

● Compact corner utilization: Enable 3-way/4-way tube junctions (T-cross) in ≤4m² bathrooms while maintaining ≥500kg static load capacity

● Modular function expansion: Pre-welded mounting holes allow integration of towel racks/shelves within dry-wet separation layouts

3. Special Material Applications

● Carbon fiber connectors: Reduce weight by 40% with ≥800MPa tensile strength for suspended/thin-frame designs

● For coastal/steam room installations

Note: Actual selection must consider door type (swing/slide), glass thickness (6–10mm), and wall structure.

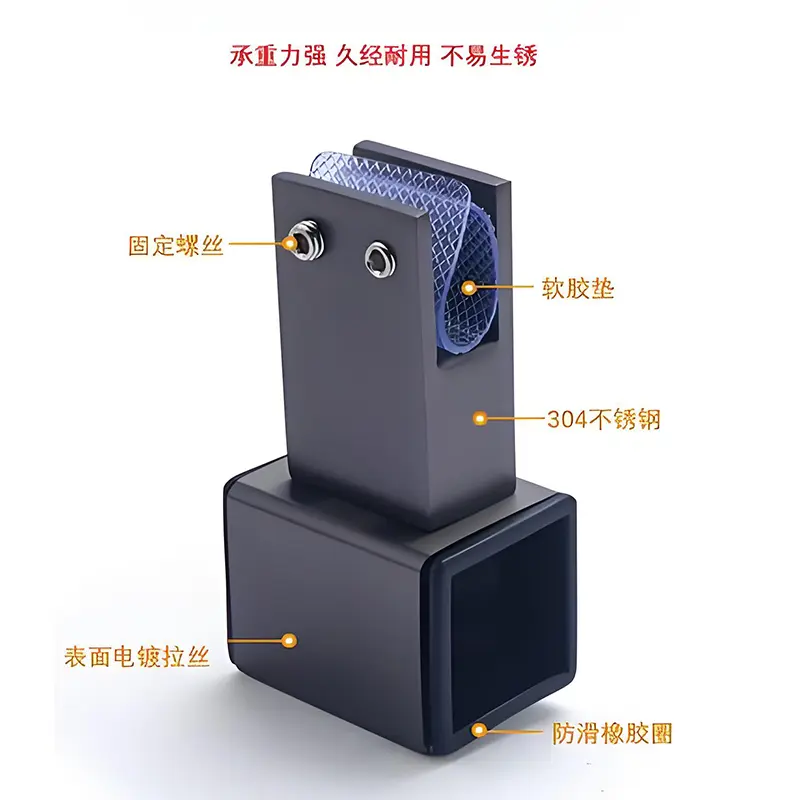

product Display

Why Choose Our Solution?

Backed by our 17-year experience and dedicated engineering support team, our connectors undergo rigorous testing. We can fulfil both the requirements of technical buyers and the needs of procurement specialists.

With the whole process of moulding, die-casting, machining, polishing, plating/powder coating/painting, inspection, assembly and shipment, we can strictly control every step of the production to ensure quality and improve product qualification rate.

Actually we provide OEM/ODM services for many famous international brands in Europe and America. For example, TOTO, Dornbracht, Roca, KLUDI.

We strictly control the thickness of plating layer of copper, nickel and chrome, usually our plating thickness is: Cu ≥ 15um, Ni ≥ 10um, Cr ≥ 0.15um, and can pass neutral 240 hours or acidic 48 hours salt spray test. We also customize your products for salt spray testing in excess of neutral 480 hours. And we promise never to use the return material directly for die-casting production.

Sincerely welcome friends from all walks of life to call us and visit our factory!